PRECISION EDM

MACHINING

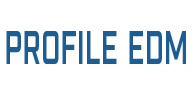

Achieve tighter tolerances and superior detail with Profile EDM, perfect for intricate designs and high-performance applications.

ABOUT US

Precision EDM Machining Backed by 30+ Years of Expertise

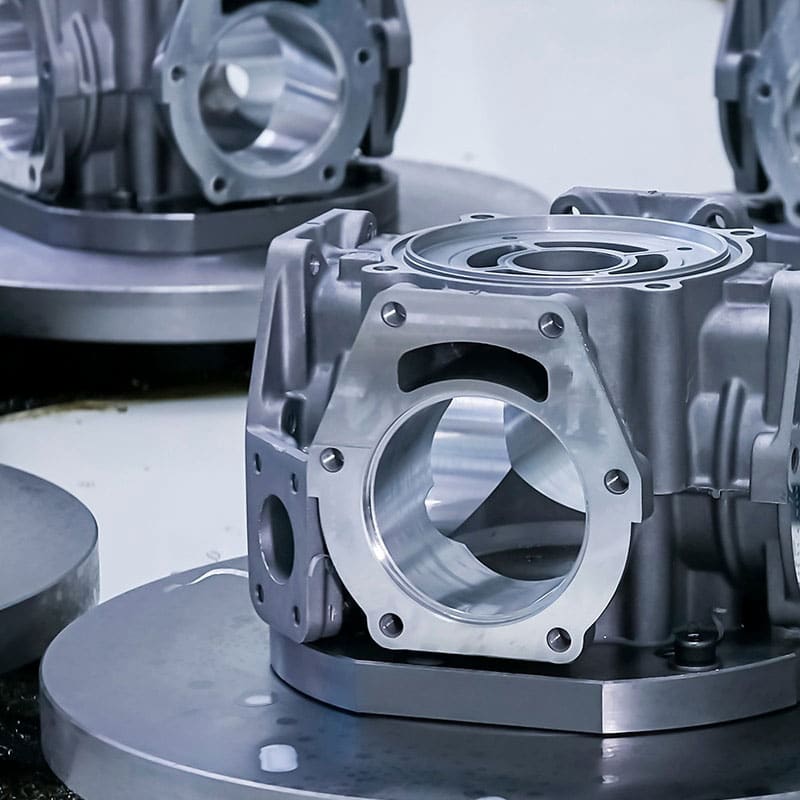

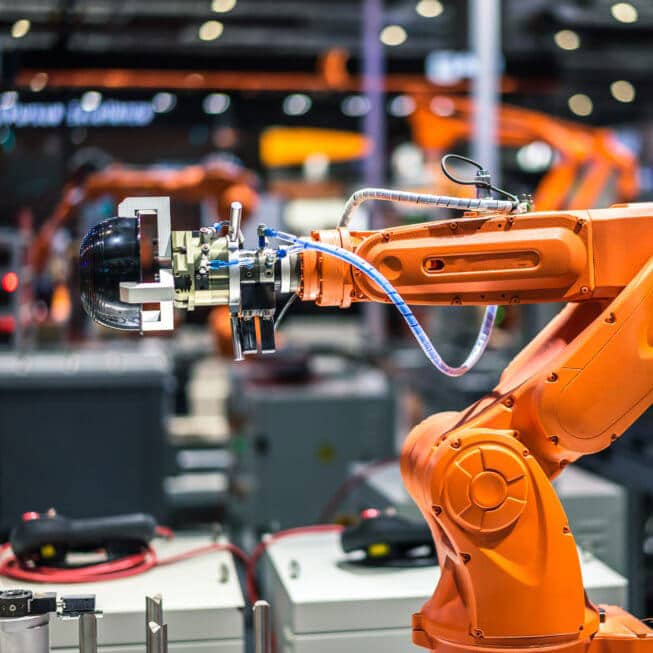

At Profile EDM, we specialize in high-precision Wire EDM machining and Fast Hole drilling, delivering parts with tolerances as tight as ±0.0003". Our state-of-the-art facility utilizes advanced CNC-operated EDM technology to produce intricate, burr-free components for industries such as aerospace, medical, automotive, electronics, and tool & die.

With over three decades of experience, our team provides expert engineering, rapid prototyping, and large-scale production capabilities. Whether you need one-off prototypes or high-volume production runs, we ensure unmatched accuracy, repeatability, and fast turnaround times.

WHAT WE DO

Precision EDM Solutions for Your Industry

Profile EDM provides cutting-edge Wire EDM Machining, Fast Hole Drilling, Prototyping, and High-Volume Production to meet the most demanding manufacturing requirements.

BENEFITS

WHY CHOOSE PROFILE EDM

Industry-Leading EDM Machining with Unmatched Precision

At Profile EDM, we combine over 30 years of expertise with state-of-the-art Wire EDM and Fast Hole drilling technology to produce precision parts with tolerances as tight as ±0.0001”. Our customers trust us for consistent accuracy, quick turnaround times, and advanced engineering solutions.

- Extreme Precision – Capable of machining complex geometries and ultra-fine details.

- Advanced EDM Technology – We utilize cutting-edge CNC-operated Wire EDM and Fast Hole drilling machines for repeatable, high-accuracy results.

- Fast Turnaround & Scalable Production – Whether you need prototypes, short runs, or full-scale production, we meet deadlines without sacrificing quality.

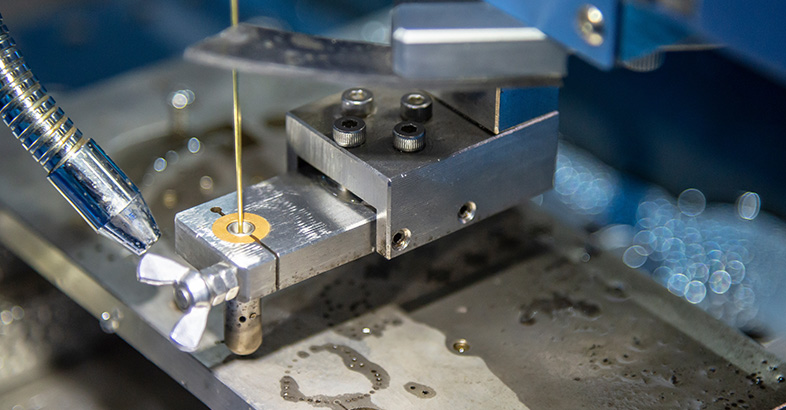

- Industry Expertise – Trusted by aerospace, medical, automotive, tool & die, and electronics industries.

FREQUENT QUESTIONS

Learn More About Wire EDM Machining

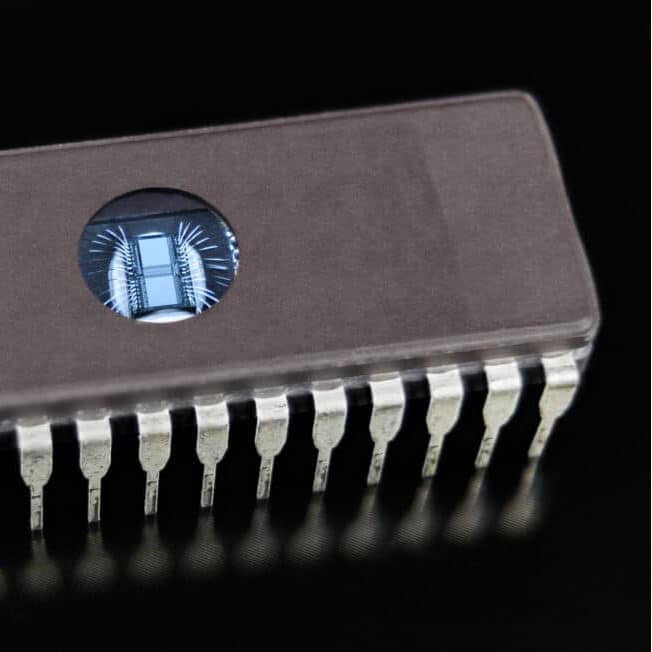

Wire EDM (Electrical Discharge Machining) is a precision cutting process used to create complex, high-accuracy parts with fine details and tight tolerances. It is widely used in industries such as aerospace, medical, automotive, electronics, and tool & die manufacturing.

Whether you’re exploring Wire EDM for the first time or need expert machining services, here are answers to common questions about this cutting-edge technology.

Wire EDM (Electrical Discharge Machining) is a non-contact precision cutting process that uses a thin, electrically charged wire to erode material via electrical discharges. The process occurs in a dielectric fluid, which flushes away debris and prevents overheating.

Wire EDM can cut electrically conductive materials, including hardened steels, aluminum, brass, titanium, tungsten, Inconel, carbide, and exotic alloys. The process works on materials up to 16 inches thick with precision tolerances.

Wire EDM offers exceptional precision, with tolerances as tight as ±0.0001”. It is ideal for complex geometries, fine details, and hard-to-machine materials, producing burr-free finishes with no mechanical stress on the part.

Unlike CNC milling, Wire EDM does not require cutting forces, making it ideal for delicate parts. It excels in cutting hardened materials, achieving extreme precision, and eliminating the need for post-processing.

The speed of Wire EDM depends on material type, thickness, and required tolerances. Generally, it cuts at speeds ranging from 0.02 to 1.5 inches per minute, with faster speeds for softer materials and high-precision slower cutting for intricate designs.

INDUSTRIES SERVED

Precision EDM Solutions for a Wide Range of Industries

Profile EDM specializes in high-precision Wire EDM and Fast Hole drilling for industries requiring extreme accuracy, intricate geometries, and burr-free finishes. We support aerospace, medical, automotive, tool & die, and more.