EDM Wire Cutting

Wire EDM (Electrical Discharge Machining) is a highly precise, non-contact cutting process that allows for the creation of intricate components with extreme accuracy. Using an electrically charged wire submerged in dielectric fluid, the material is eroded with no mechanical stress and no heat distortion, ensuring clean, burr-free edges.

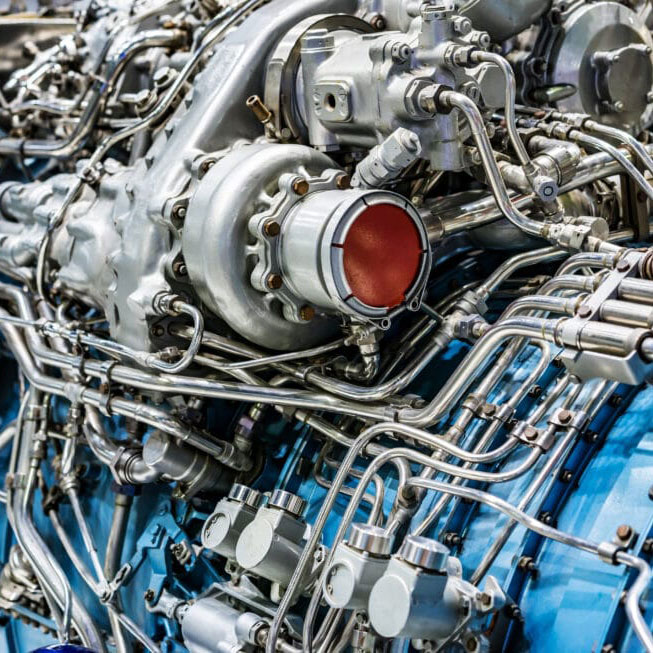

At Profile EDM, we specialize in Wire EDM machining for industries that demand exceptional precision, including aerospace, medical, automotive, electronics, and tool & die manufacturing. Our advanced technology enables us to achieve tolerances as tight as ±0.0001”, making us a trusted partner for high-precision components.

Whether you require prototype development, small production runs, or high-volume manufacturing, our state-of-the-art EDM machines are capable of delivering superior results with minimal material waste and maximum repeatability.

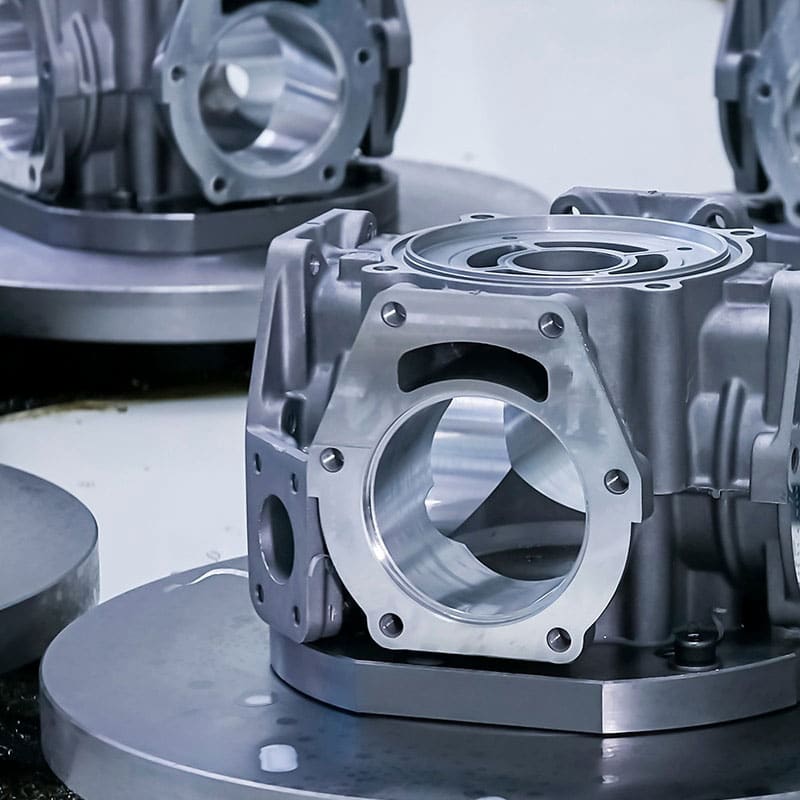

Our Wire EDM technology allows us to cut materials that are difficult or impossible to machine using conventional methods. With no cutting force, delicate or complex parts can be produced without risk of deformation.

From thin-walled components to high-strength alloys, our Wire EDM capabilities provide cost-effective and precise solutions for industries requiring high-performance components.

The ability to machine hardened materials makes Wire EDM an ideal solution for tooling and die-making applications. We provide custom solutions for progressive dies, extrusion dies, form tools, and precision jigs & fixtures.

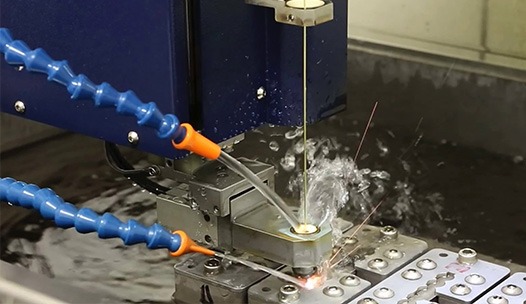

Material Preparation

The workpiece, made of electrically conductive material, is secured and submerged in a dielectric fluid.

Wire Threading

A thin, electrically charged wire (typically brass or coated wire) is automatically threaded through a pre-drilled hole or edge of the material.

Electrical Discharge Machining

A high-frequency electrical current passes through the wire, creating controlled sparks that erode the metal along the programmed cutting path.

Precision Cutting

The wire moves along a programmed tool path, tracing complex geometries with tolerances as tight as ±0.0001".

Dielectric Fluid Flushing

A dielectric liquid (deionized water) continuously flushes away debris and cools the workpiece, ensuring smooth and burr-free edges.

Final Inspection & Finishing

Each cut part undergoes precision inspection to ensure it meets exact specifications before being prepared for delivery.

Whether you need prototypes, small batch production, or large-scale manufacturing, Profile EDM is equipped to deliver high-precision results with fast turnaround times. Our commitment to quality assurance ensures every part is meticulously inspected to meet your exact specifications.