Fast Hole Drilling

Fast Hole Drilling (Electrical Discharge Machining Hole Drilling) is a non-contact machining process designed for creating small-diameter, deep, and precision-drilled holes in hard or difficult-to-machine materials. Using an electrically charged electrode and dielectric fluid, Fast Hole drilling produces precise, burr-free holes without mechanical stress.

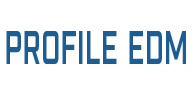

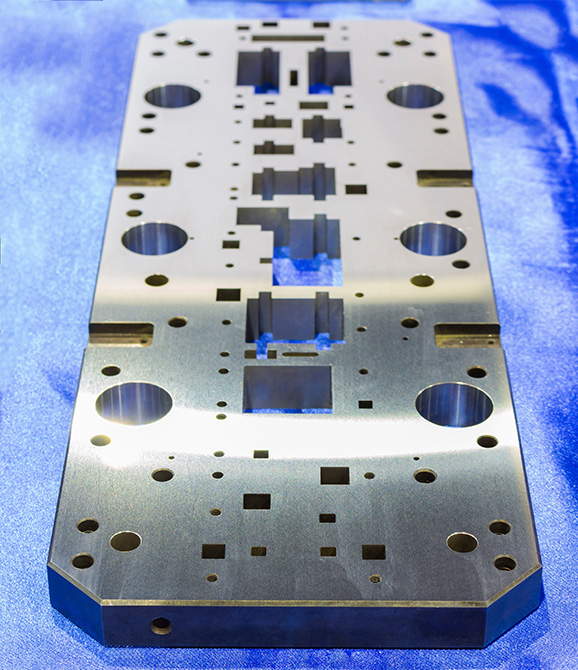

At Profile EDM, we utilize advanced Fast Hole drilling technology to serve industries that require high-precision hole placement, including aerospace, medical, automotive, and tool & die manufacturing. With our state-of-the-art equipment, we achieve hole diameters as small as 0.010” and depths of up to 20 times the hole diameter, ensuring consistent and repeatable accuracy.

Whether you need micro-hole drilling, cooling holes for turbine components, or precision starter holes for Wire EDM cutting, our Fast Hole drilling services provide a reliable and cost-effective solution for your machining needs.

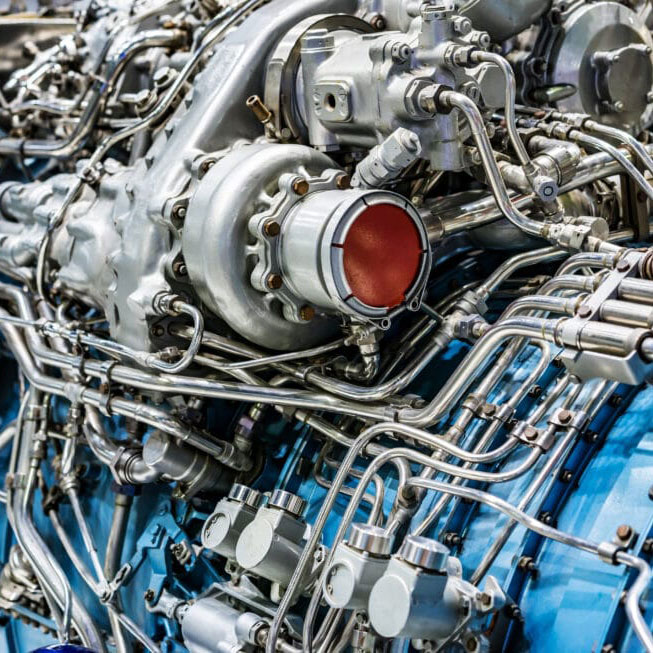

Unlike traditional drilling methods, Fast Hole drilling uses no cutting force, making it an excellent option for heat-sensitive and ultra-hard materials. This ensures no micro-cracks, tool wear, or mechanical deformation in the final component, even when working with the most challenging alloys.

Because the process is based on electrical discharges rather than mechanical cutting, Fast Hole drilling can create small-diameter, high-aspect-ratio holes with extreme accuracy, even in materials that would otherwise be impossible to machine. The absence of direct contact eliminates stress on delicate components, allowing for the machining of thin-walled structures and intricate geometries with ease.

From fuel injector holes in aerospace components to cooling holes in turbine blades, our Fast Hole drilling services provide ultra-precise, high-quality results for demanding applications. Additionally, this technique is ideal for creating starter holes for Wire EDM cutting, ensuring efficient processing of complex parts while maintaining consistently tight tolerances from start to finish.

Because Fast Hole drilling can create intricate, deep, and precise holes, it is widely used for medical devices, mold and die components, and high-performance automotive parts. At Profile EDM, we tailor our services to meet your specific requirements, ensuring you receive the best quality and performance.

Material Setup

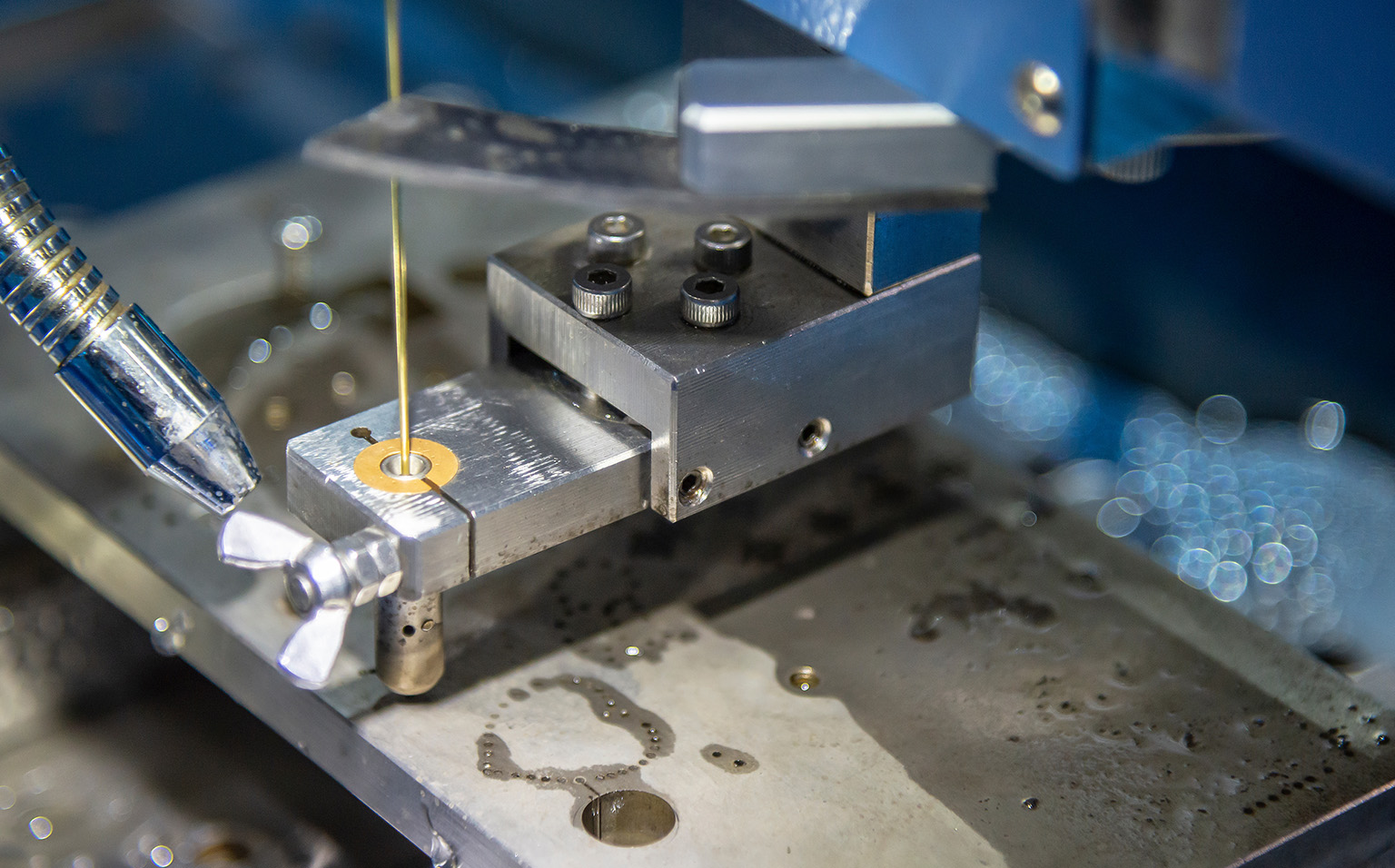

The workpiece, made of conductive material, is secured in the EDM drilling machine and submerged in dielectric fluid.

Electrode Positioning

A small-diameter, electrically charged electrode is aligned with the designated hole location.

Electrical Discharge

High-frequency electrical pulses generate controlled sparks that erode the metal, creating a precise hole.

Dielectric Flushing

A dielectric fluid flushes away debris, cools the material, and ensures a clean, burr-free hole.

Final Inspection

Each drilled hole undergoes rigorous inspection to ensure precise dimensions and compliance with industry standards.

Whether you need single-hole drilling, multi-hole arrays, or specialized hole geometries, Profile EDM provides unmatched precision and repeatability. Our commitment to quality assurance ensures that every part meets your exact specifications.