Bulk Production

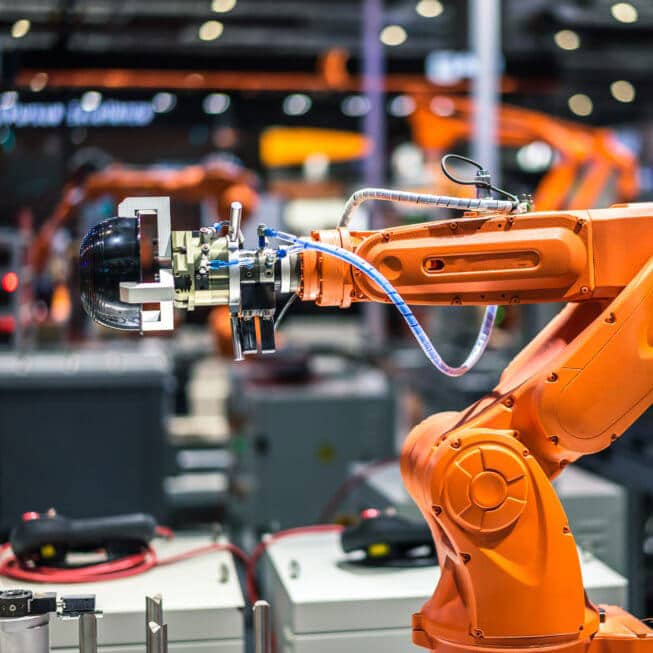

Bulk EDM Production at Profile EDM offers precision machining solutions for high-volume manufacturing while maintaining tight tolerances and repeatable accuracy. Whether you require thousands of identical components or a large batch of complex parts, our advanced EDM technology ensures superior quality in every piece.

With automated Wire EDM and Fast Hole drilling, we provide a cost-effective solution for industries that demand high-volume production with consistent part uniformity. Our facility is equipped to handle multi-shift production cycles, reducing lead times while maintaining stringent quality standards.

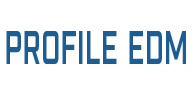

From aerospace and medical components to automotive and industrial tooling, our bulk EDM production services ensure efficiency, accuracy, and reliability at scale.

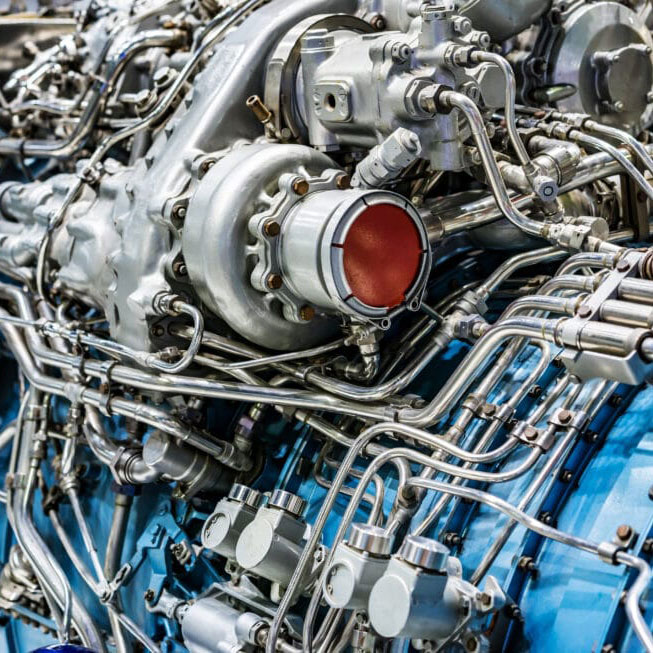

Our bulk production process leverages **automated EDM systems** to ensure precise part replication with minimal operator intervention. This results in faster turnaround times while maintaining industry-leading tolerances for even the most intricate components.

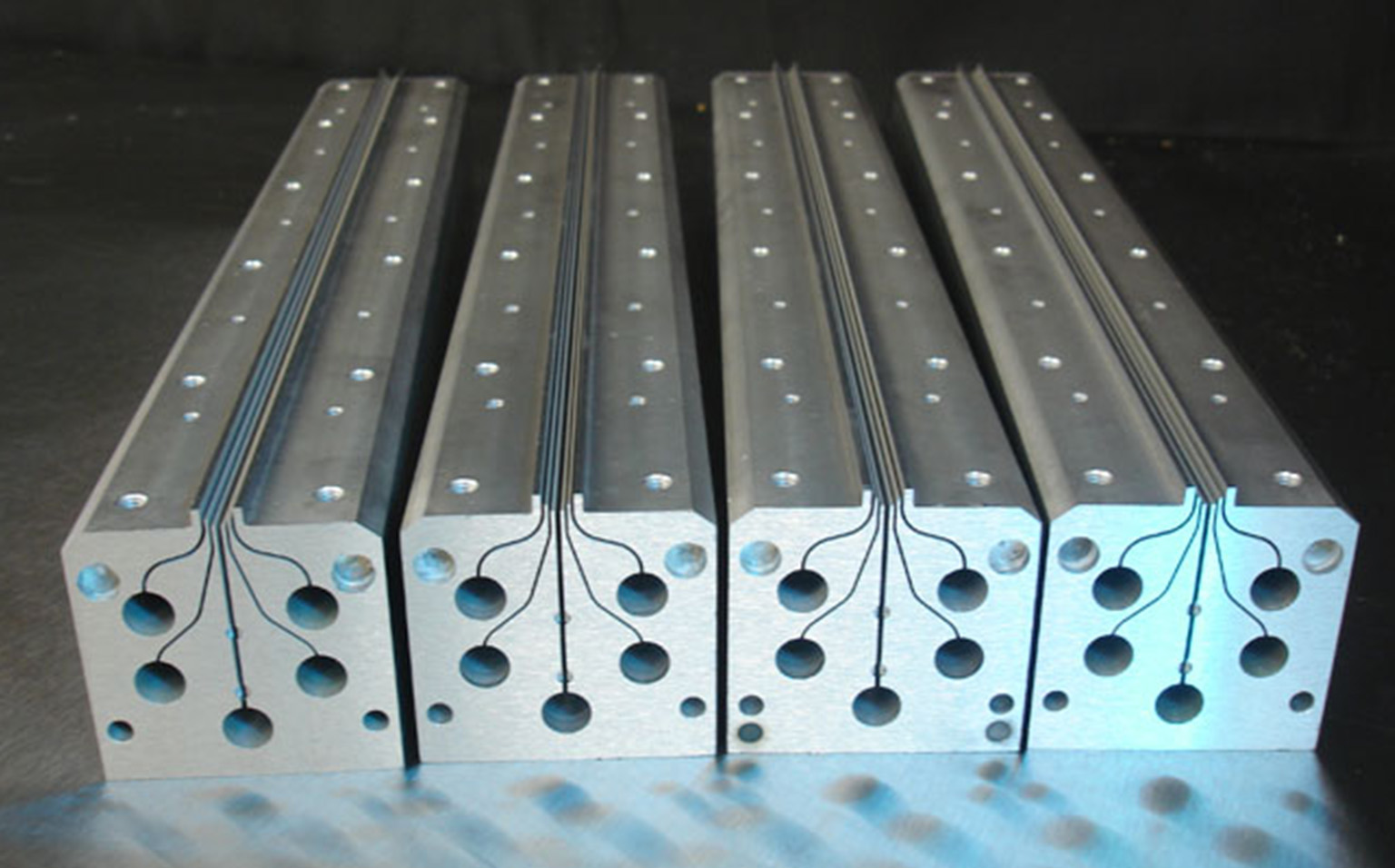

By utilizing multi-axis EDM machining, we efficiently produce complex geometries without secondary operations. This streamlines production and minimizes material waste, making EDM an excellent choice for high-performance industries requiring both precision and cost control.

From precision stamping dies to medical-grade surgical tools, our bulk EDM manufacturing process ensures your parts are produced to exact specifications, ready for immediate assembly or final processing.

At Profile EDM, we understand that high-volume manufacturing requires both speed and precision. Our automated EDM solutions are designed to deliver high-quality, repeatable results with minimal setup time, reducing costs while maximizing efficiency.

Production Planning

Assessing project requirements, tolerances, and material selection for bulk production.

Automated EDM Setup

Configuring multi-axis EDM machines for high-precision, repeatable part manufacturing.

Precision Cutting

Using Wire EDM and Fast Hole drilling to create intricate components with extreme accuracy.

Quality Control

Each part undergoes rigorous inspection to ensure precise tolerances and high-quality standards.

Batch Completion

Bulk orders are completed efficiently, ready for final assembly or customer delivery.

Shipping & Fulfillment

Parts are packaged and shipped, meeting strict customer timelines and specifications.

With Profile EDM, you get scalable, high-precision manufacturing that meets the demands of bulk production. Our team ensures quality control, cost efficiency, and on-time delivery for every project.

INDUSTRIES SERVED

Precision EDM Solutions for a Wide Range of Industries

Profile EDM specializes in high-precision Wire EDM and Fast Hole drilling for industries requiring extreme accuracy, intricate geometries, and burr-free finishes. We support aerospace, medical, automotive, tool & die, and more.